While the effects of fossil fuels have been a cause of concern in the past few years, the new emerging hydrogen-powered engines have been making their way into different industries, more prominently in the transportation industry.

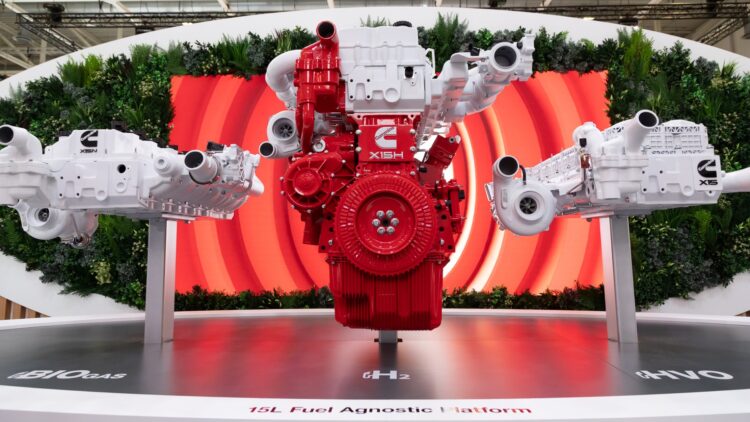

Cummins Inc.’s 15-liter hydrogen internal combustion engine can revolutionize the face of energy and engines in America.

This is how hydrogen fuel engines can fight climate change

Hydrogen fuel has long been considered a potential substitute for conventional fossil fuels mainly because it can be generated with nil carbon emission. In contrast to the standard gasoline and diesel engines that produce undesirable greenhouse gases, hydrogen engines produce only water.

Cummins Inc.’s 15-litre hydrogen engine goes further with the same highly effective internal combustion engine layout but with clean, green hydrogen fuel. This approach has great potential for considerably cutting emissions and placing hydrogen at the heart of the worldwide effort to transition to sustainability.

The internal combustion engine, which may be associated with large consumption of fuel through large cars, is also in the process of transformation. In the same way, the engine emits no direct carbon emission if it uses hydrogen instead of conventional fuel.

Hydrogen-powered engines: key to transforming heavy-duty transport

The hydrogen combustion process is virtually free from carbon, making it a perfect fit for industries that want to reduce emissions but cannot switch to new technologies such as fuel cells or EVs. The 15-liter hydrogen engine developed on the fuel-agnostic architecture is new from Cummins, an engine design that can support several fuel types.

The components below the head gasket are not very much affected, while those above are adapted depending on the fuel used. This ability to adjust makes the hydrogen engine a feasible current application and a potential long-term answer to the energy riddle. Since 2021, Cummins has been experimenting with hydrogen engines, and the results have been positive.

The 15-l hydrogen engine has already shown good power and torque, and its prototypes have produced more than 810 ft-lb of torque and 290 horsepower. This makes the hydrogen engine ideal for heavy-duty applications such as trucks and commercial vehicles, which are essential in the economy.

The road to a cleaner future: hydrogen engine mass production plans

The global shift toward zero-emission technology has accelerated in recent years as countries across the globe committed to emissions reduction goals. Hydrogen is central to this process, especially in sectors where electrification is challenging, such as freight transport, for which electric trucks cannot yet contend with the range requirements.

With hydrogen costing at least 50% less than battery electric vehicles and without substantial changes to vehicle design, Cummins’ hydrogen engine is a practical and feasible means to reduce carbon emissions.

For example, ICE hydrogen cars can eliminate the need for expensive infrastructure adjustments that are characteristic of battery electric vehicles. The hydrogen engine gives an already-known technology to the fleets and manufacturers of vehicles, thus fast-tracking the rate at which the technology is adopted in the existing markets.

Furthermore, although hydrogen fuel production is expensive, it can be generated through electrolysis and thus can be made entirely carbon-free by using renewable energy sources such as wind or solar power.