Cummins has kicked off production of its latest hydrogen internal combustion engines (H2-ICE) for Tata Motors at a brand-new facility in Jamshedpur, India. This new engine will help Tata Motors and Cummins showcase a practical, zero-carbon power option, pushing the decarbonization of India’s commercial vehicle industry forward. Here’s more about this one-of-a-kind invention.

The new hydrogen engine

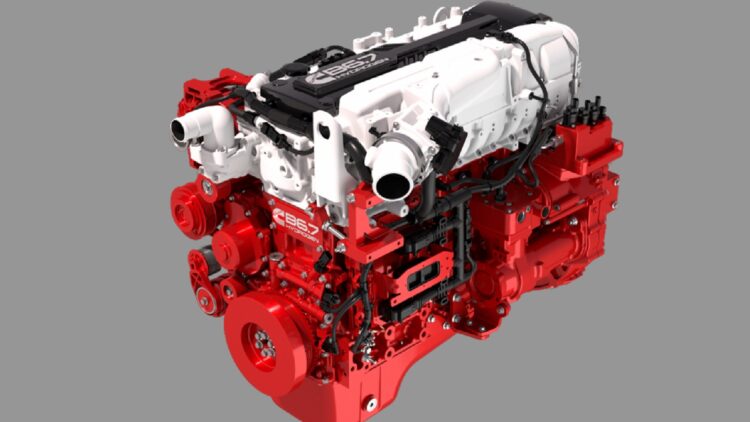

The first B6.7H hydrogen engines rolled off the line in March and are set to be installed in Tata Motors’ trucks. The B6.7H engine shares many parts with current diesel and natural gas engines, fits right where a standard engine goes, and can be refueled in just minutes.

The new Jamshedpur site just kicked off hydrogen engine production, marking the latest milestone in the Cummins and Tata Motors partnership in India. This new manufacturing facility is a 50/50 joint venture between Tata Motors and Cummins, and it’s set to produce hydrogen internal combustion engines for medium and heavy-duty commercial vehicles. They’ll also be working on other low-to-zero emissions tech like batteries and hydrogen fuel cells.

At the launch, Ashwath Ram, managing director of Cummins Group in India, said, “Cummins has always believed in bringing the right technology at the right time to help our customers succeed. We’re all about pushing advanced low to zero-emissions tech to market as we work towards decarbonizing the on-highway industry. Partnering with innovative companies like Tata Motors helps make this goal a reality.”

Tata Motors and Cummins have been working together for 30 years through their joint venture, Tata Cummins Private Limited (TCPL). In March 2023, they formed TCPL GES, a subsidiary focused on designing and developing low and zero-emission propulsion tech for commercial vehicles in India.

Trekking towards a more sustainable future

Cummins is working hard towards its goal of zero emissions by 2050 as part of its Planet 2050 strategy. Their Destination Zero roadmap outlines how they plan to achieve this, focusing on making low-to-zero emission technologies more available and viable, driving the industry’s decarbonization.

From lead-acid battery-powered three-wheelers to high-capacity electric city buses, the Indian commercial vehicle (CV) industry has made impressive strides in electrification over the past decade. As one of the largest in the world, both in terms of demand and local manufacturing, the Indian truck and bus industry is known for being frugal and traditional. This makes it challenging for new technologies and market trends to catch on quickly. The commercial and demanding nature of this segment doesn’t easily allow for sweeping changes either.

Despite the limited numbers and market reach, the push towards electrification in India’s CV sector is a notable achievement. The city bus transportation and last-mile delivery segments are leading the charge, with commercial EVs sales growing by 169% in India last year. The shift is so significant that recent tenders for city buses by state-owned transport undertakings (STUs) in various Indian cities are mostly for electric buses, replacing CNG buses, which were once the top “green” option.